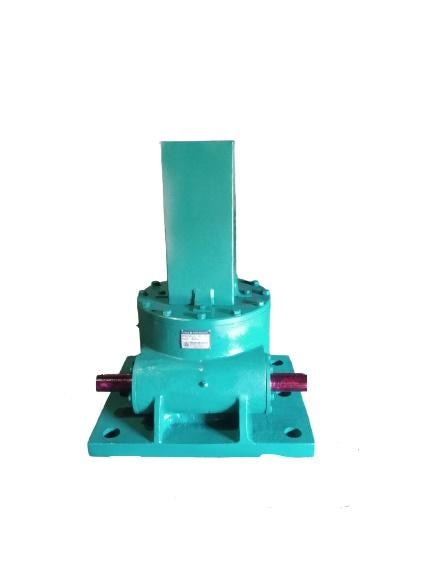

Screw Jack for REM ROLL GAP ADJUSTMENT TYPE :- Z0285.02.05.03 REM A screw jack for REM (Rolling Element Module) roll gap adjustment is a mechanical device used to adjust the gap between rolls in various industrial processes, such as: 1. Steel mills 2. Aluminum mills 3. Paper mills 4. Textile mills 5. Printing presses The screw jack is used to precision-adjust the roll gap to control factors like: 1. Thickness 2. Tension 3. Pressure 4. Surface finish Key features of screw jacks for REM roll gap adjustment: 1. High precision and accuracy 2. Compact design 3. Reliable and durable 4. Easy to install and maintain 5. Corrosion-resistant materials (e.g., stainless steel) 6. Customizable to specific application requirements Benefits: 1. Precise control over roll gap 2. Improved product quality 3. Reduced production downtime 4. Increased process efficiency 5. Enhanced safety When selecting a screw jack for REM roll gap adjustment, consider factors like: 1. Load capacity 2. Stroke length 3. Screw pitch and lead 4. Material compatibility 5. Precision requirements By using a screw jack for REM roll gap adjustment, industries can achieve precise control over their processes, resulting in improved product quality and increased efficiency. #Screw-Jack-For-REM-ROLL-GAP-ADJUSTMENT-In-Ahmedabad #Screw-Jack-For-REM-ROLL-GAP-ADJUSTMENT-In-Gujarat #Screw-Jack-For-REM-ROLL-GAP-ADJUSTMENT-In-India

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Submit Your Enquiry