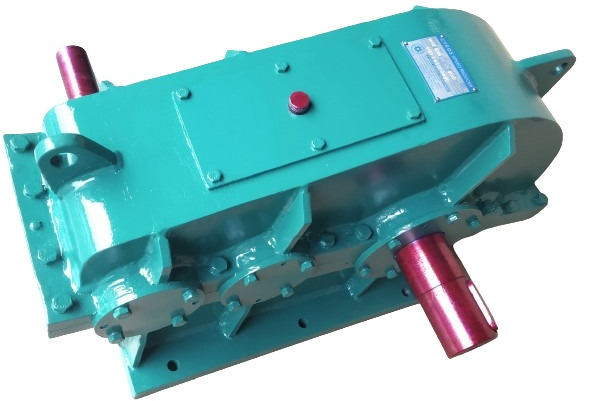

Helical Gearbox HR:400 Ratio 50:1 Helical gearboxes have numerous applications in various industries due to their unique characteristics, such as: 1. *High efficiency*: Helical gears have a higher contact ratio, resulting in smoother operation and reduced energy loss. 2. *High torque density*: Helical gearboxes can handle high torque loads while maintaining a compact design. 3. *Low noise*: The angled teeth on helical gears reduce vibration and noise, making them ideal for quiet operations. 4. *High precision*: Helical gearboxes provide precise speed and position control, essential for applications requiring accuracy. Some common uses of helical gearboxes include: 1. *Industrial machinery*: Printing, textile, and food processing machines. 2. *Robotics*: Precise motion control and high torque density make helical gearboxes ideal for robotic arms and grippers. 3. *Automotive*: Helical gearboxes are used in car transmissions, transfer cases, and differentials. 4. *Aerospace*: High-reliability and precision requirements make helical gearboxes suitable for aircraft and spacecraft applications. 5. *Medical devices*: Precise motion control and low noise make helical gearboxes suitable for medical equipment like surgical robots and hospital beds. 6. *Material handling*: Conveyor systems, cranes, and hoists benefit from the high torque density and precision of helical gearboxes. 7. *Marine*: Helical gearboxes are used in propulsion systems, winches, and steering gear for boats and ships. Helical gearboxes are versatile and can be customized to suit specific application requirements. #Helical-Gearbox-Manufacturer-In-Ahmedabad #Helical-Gearbox-Manufacturer-In-Gujarat #Helical-Gearbox-Manufacturer-In-India

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Helical Gearbox HR:400 Ratio 50:1 Helical gear...

2024-07-13T13:50:27

Helical Gearbox HR:400 Ratio 50:1 Helical gearboxes have numerous applications in various industries due to their unique characteristics, such as: 1. *High efficiency*: Helical gears have a higher contact ratio, resulting in smoother operation and reduced energy loss. 2. *High torque density*: Helical gearboxes can handle high torque loads while maintaining a compact design. 3. *Low noise*: The angled teeth on helical gears reduce vibration and noise, making them ideal for quiet operations. 4. *High precision*: Helical gearboxes provide precise speed and position control, essential for applications requiring accuracy. Some common uses of helical gearboxes include: 1. *Industrial machinery*: Printing, textile, and food processing machines. 2. *Robotics*: Precise motion control and high torque density make helical gearboxes ideal for robotic arms and grippers. 3. *Automotive*: Helical gearboxes are used in car transmissions, transfer cases, and differentials. 4. *Aerospace*: High-reliability and precision requirements make helical gearboxes suitable for aircraft and spacecraft applications. 5. *Medical devices*: Precise motion control and low noise make helical gearboxes suitable for medical equipment like surgical robots and hospital beds. 6. *Material handling*: Conveyor systems, cranes, and hoists benefit from the high torque density and precision of helical gearboxes. 7. *Marine*: Helical gearboxes are used in propulsion systems, winches, and steering gear for boats and ships. Helical gearboxes are versatile and can be customized to suit specific application requirements. #Helical-Gearbox-Manufacturer-In-Ahmedabad #Helical-Gearbox-Manufacturer-In-Gujarat #Helical-Gearbox-Manufacturer-In-India

2024-07-13T13:50:27

Keywords

- 400 Ratio

- Low noise

- common uses

- energy loss

- robotic arms

- steering gear

- hospital beds

- Helical gears

- precise speed

- transfer cases

- compact design

- High precision

- surgical robots

- Medical devices

- Helical Gearbox

- High efficiency

- Conveyor systems

- quiet operations

- position control

- Material handling

- medical equipment

- car transmissions

- high torque loads

- propulsion systems

- smoother operation

- various industries

- High torque density

- Industrial machinery

- higher contact ratio

- numerous applications

- unique characteristics

- precision requirements

- Precise motion control

- spacecraft applications

- food processing machines

- specific application requirements

Submit Your Enquiry